Feasibility analysis of using Raymond mill for pyrophyllite grinding

Date:2021-01-11 Views:2529

Pyrophyllite is a layered hydrated aluminosilicate clay mineral. Usually processed into crafts. Pyrophyllite after grinding is often used as paint, and it is also a good raw material for making siding. Pyrophyllite is a very soft silicate mineral. Because its Mohs hardness is between 1-2, there are many milling equipment available. The following is the feasibility analysis of Raymond mill for pyrophyllite milling.

Feasibility analysis of Raymond mill for pyrophyllite grinding

1. The Raymond mill is mainly suitable for grinding various non-flammable and explosive ore materials with Mohs hardness not greater than 9.3 and humidity below 6%. Pyrophyllite is a kind of very soft silicate mineral. The Mohs hardness is between 1-2, which is completely within the grinding range of Raymond mill;

2. The fineness of the pyrophyllite powder after being ground by the Raymond mill is better, and it can be directly used in production without further processing. Therefore, compared with other equipment that requires multiple repeated grinding treatments, the Raymond mill is more efficient.

Process steps of pyrophyllite grinding process

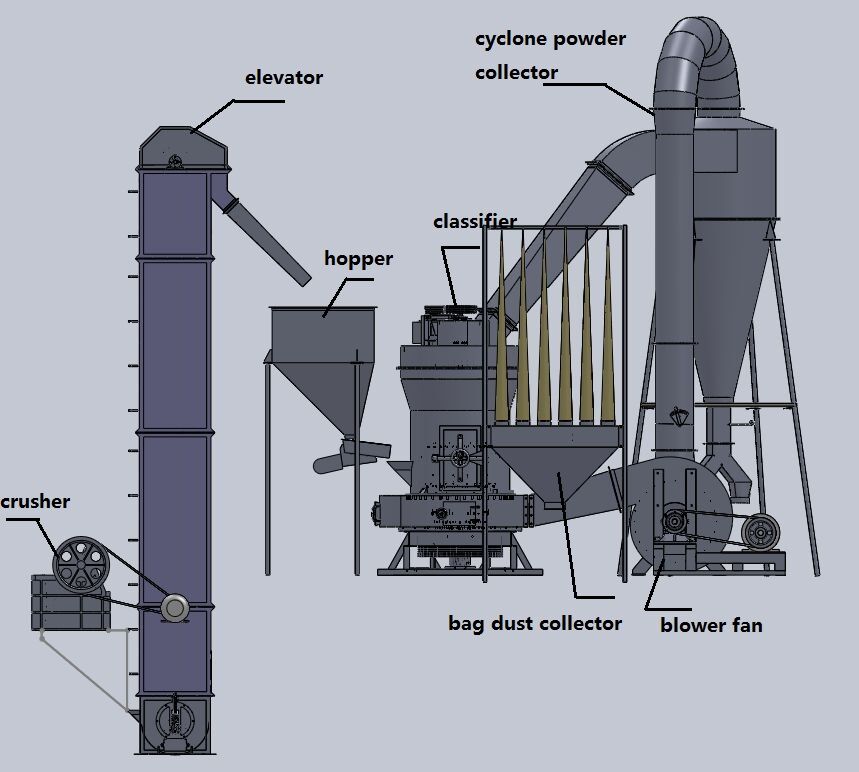

The first stage: crushing

Large pieces of pyrophyllite are transported to the raw material warehouse by a special vehicle, and then the material is sent to the jaw crusher by a forklift/manually for crushing, and crushed to be smaller than the rated feed size of the Raymond mill;

The second stage: feeding

The pyrophyllite crushed by the jaw crusher is lifted by the elevator to the storage hopper, and the storage hopper is discharged, and the feeder feeds the main machine of the Raymond mill evenly;

The third stage: grinding

Qualified products in the grinding process are screened by the screening system and then enter the collector through the pipeline. After collection, they are discharged through the powder outlet tube to become the finished product, and then discharged through the powder outlet tube to become the finished powder. The unqualified products fall into the main engine of the Raymond mill and re-grind until the discharge particle size is met.

The advantages of using Raymond mill for pyrophyllite mill

1. The fineness of the finished pyrophyllite powder after being ground by the Raymond mill is uniform, and the sieving rate can reach 99%;

2. Raymond mill is a high-end milling equipment that integrates crushing, drying, grinding, and grading and conveying. Its system is simple, the layout is compact, the floor space is small, and it can be laid out in the open air, so compared to Other grinding equipment, this machine can greatly reduce investment costs;

3. The important parts of the machine are made of good castings and profiles, and the craftsmanship is fine, which then greatly improves the wear resistance of the whole machine.

Therefore, based on the above analysis, Raymond mill is an excellent choice for grinding pyrophyllite. For more information about the pyrophyllite production line, please feel free to consult online or leave a message. Shanghai Clirik Machinery Co.,Ltd. specializes in producing all kinds of mine crushing and grinding equipment. Welcome to inquire.

Phone: 008613917147829/0086-21-20236178

E-mail: info@clirik.com

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201,China.