Introduction of the new Raymond mill with a particle size of 100 mesh

Date:2020-08-24 Views:2506

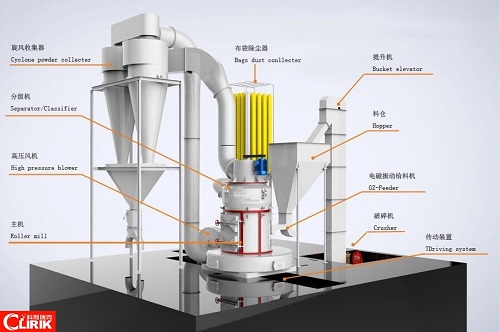

For processing ore and mineral powder, the new Raymond mill equipment is a grinding equipment that facilitates efficient production. Clirik provides Raymond mill 100 mesh new equipment and a complete set of professional milling production line solutions to enhance the value of non-metallic ore powders such as dolomite, marble, limestone, barite, and kaolin, creating considerable profits and value. This article focuses on introducing the new Raymond mill equipment for grinding 80-400 mesh powder.

Introduction to the special equipment for Raymond Mill with 100 mesh

What kind of pulverizer can be used to grind mineral powder with a particle size of 100 mesh? Mill manufacturer Clirik provides new Raymond mill equipment to produce. These are environmentally friendly and energy-saving new Raymond mill equipment that can help achieve efficient production and processing.

Let’s first understand the YGM Raymond mill. This is a newly upgraded new Raymond mill equipment. The fineness of the powder that can be produced can be adjusted between 80-400 mesh, with uniform fineness, full particle shape, and classification efficiency. High, there are a lot of materials that can be ground. Various non-metallic minerals with Mohs hardness below 7 and humidity within 6% can be milled.

Clirik New Raymond Mill-YGM Raymond Mill

*Production capacity*: 1-25t/h

*Finished product size*: 22-180μm

*Application areas*: This mill is a replacement equipment for traditional Raymond mills, and is widely used in production and life fields such as papermaking, coatings, plastics, rubber, inks, pigments, building materials, medicine, and food.

*Practical materials*: It has high-yield and efficient grinding ability for various non-metallic mineral materials with Mohs hardness below 7 and humidity within 6%, such as talc, calcite, calcium carbonate, dolomite, potash feldspar, and bentonite , Kaolin, clay, graphite, pottery clay, zircon sand, bentonite and other non-minerals have good grinding effect.

Let’s get to know the HGM improved ultra-fine mill, which is also a type of ultra-fine mill equipment favored by the market and customers. It has a large conveying capacity and a large amount of shoveling. It adopts a maintenance-free grinding roller assembly and a new plum frame structure. , Equipment operation is more reliable, maintenance is more convenient, and the system is upgraded, the configuration is more reasonable, the output is higher, and the new large blade is used, and the shoveling amount is larger.

Clirik environmental protection mill-HGM improved ultra fine grinding mill equipment

*Production capacity*: 1.5-13t/h

*Finished product size*: 38-180μm

*Application areas*: This mill is an upgraded product of traditional mills, and is widely used in papermaking, coatings, plastics, rubber, inks, pigments, building materials, medicine, food and other fields.

*Practical materials*: It has high-yield and efficient grinding ability for various non-metallic mineral materials with Mohs hardness below 7 and humidity within 6%, such as activated carbon, coal gangue, wollastonite, talc, calcite, calcium carbonate , Dolomite, potash feldspar, bentonite, kaolin, clay, zircon sand, bentonite and other non-minerals have good grinding effect.

How much does the new Raymond Mill sell for?

Equipment quotation is the main information that many customers want to know. As a manufacturer, Clirik is customer-centric, market-oriented, and provides tailor-made design and selection solutions based on project needs, focusing on grinding materials, fineness, production capacity, and installation Regional and other information, exclusive selection and configuration schemes can be customized, and the quotation of Raymond mill equipment provided can be more scientific and reasonable based on the customer's investment needs.

Welcome to learn more about the special equipment for Clirik Raymond grinding 100 mesh at any time. Clirik's new generation Raymond grinding mechanism has high powder efficiency, energy saving and consumption reduction, and a greater powder output rate, which can meet the grinding needs of non-metallic mine projects. Welcome to call the equipment Consult the hotline for details on the selection plan and product quotation.

If you want to know the Raymond mill price or have any questions about Raymond mill, please do not hesitate to contact us.

Phone: 008613917147829/0086-21-20236178

E-mail: info@clirik.com

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201,China.