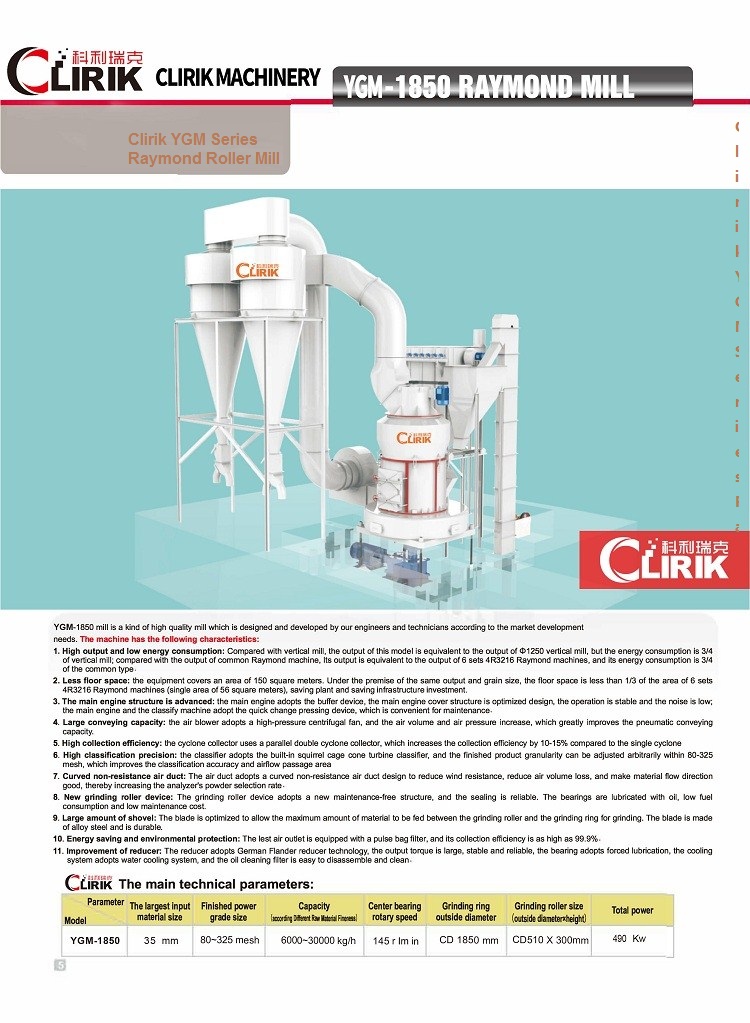

CLIRIK YGM1850 Raymond Grinding Roller Mill

Introduction of CLIRIK YGM1850 Raymond Grinding Roller Mill

Name: Clirik YGM Series Raymond Grinding Roller Mill

Model: YGM series

Brand: Clirik

Powder Fineness Process Ability: 50-450 mesh

Capacity: according to your demand about powder fineness, the finial capacity can be adjusted between 0.5-28 t/h

Use Range: can be used in more than 300 kinds of stone materials powder grinding, such as: calcite, calcium carbonate, dolomite, gypsum, carbon black, gypsum, kaolin, marble and so on

Application: mining, chemiscal, transport and many other different areas

| Model | Roller | Ring |

Feeding Size(mm) |

Finished Size(mm) |

Mill System Power(KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

|

Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1.0-3.0 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12.0 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16.0 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8.0-20.0 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28.0 | 11550*9500*10500 |

Advantages of YGM1850 Raymond Grinding Roller Mill

2. Less floor space: the equipment covers an area of 150 square meters. Under the premise of the same output and grain size, the floor space is less than 1/3 of the area of 6 sets 4R3216 Raymond machines (single area of 56 square meters), saving plant and saving infrastructure investment.

3. The main engine structure is advanced: the main engine adopts the buffer device, the main engine cover structure is optimized design, the operation is stable and the noise is low;

the main engine and the classily machine adopt the quick change pressing device, which is convenient for maintenance.

4. Large conveying capacity: the air blower adopts a high-pressure centrifugal fan, and the air volume and air pressure increase, which greatly improves the pneumatic conveying capacity.

5. High collection efficiency: the cyclone collector uses a parallel double cyclone collector, which increases the collection efficiency by 10-15% compared to the single cyclone

6. High clas sification precision: the classifer adopts the built-in squirel cage cone turbine classifer, and the finished product granularity can be adjusted arbitrarily within 80-325 mesh, which improves the classification accuracy and airflow passage area

7. Curved non-resistance air duct: The air duct adopts a curved non-resistance air duct design to reduce wind resistance, reduce air volume loss, and make material flow direction good, thereby increasing the analyzer's powder selection rate.

8. New grinding roller device: The grinding roller device adopts a new maintenance-free structure, and the sealing is reliable. The bearings are lubricated with oil, low fuel consumption and low maintenance cost.

9. Large amount of shovel: The blade is optimized to alow the maximum amount of material to be fed between the grinding roller and the grinding ring for grinding. The blade is made of alloy steel and is durable.

10. Energy saving and environmental protection: The lest air outlet is equipped with a pulse bag filter, and its collection efficiency is as high as 99.9%.

11. Improvement of reducer: The reducer adopts German Flander reducer technology, the output torque is large, stable and reliable, the bearing adopts foroed lubrication, the cooling system adopts water cooling system, and the oil cleaning filter is easy to disassemble and clean.

Application of YGM1850 Raymond Grinding Roller Mill

YGM Raymond roller mill is mainly used for grinding the material with middle and low hardness, below 6% moisture, and the material should be non-explosion and non-flammability, such as: calcite, chalk,limestone, dolomite, kaolin, bentonite, steatite, mica, magnetite,iolite, pyrophillite, vermiculite, meerschaum, attapulgite, diatomite, barite, gypsum, alunite, graphite, fluorite, phosphate ore, potassium ore pumice, etc

YGM1850 Raymond Grinding Roller Mill Manufacturer-Shanghai Clirik Machinery Co.,Ltd.

YGM raymond grinding roller mill customer visiting