Ouput Size: 0.613-0.033 micron (40-400 mesh)

Capacity: 1-25 t/h

D97 <325 mesh

2μm <10%

Raymond Roller Grinding Mill Machine also named Raymond Mill, Raymond Roller Mill, 3R/4R/5R/6R Roller Mill and Raymond Mill Machine. It is widely applied in ore materials grinding.

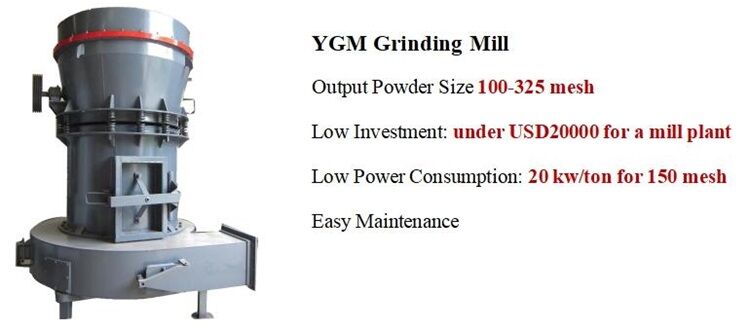

Raymond mill is the key equipment of powder production line. It is suitable for powder processing below 400 mesh. It is an ideal equipment for powder processing plants with small and medium output.

Available Materials

Raymond Roller Grinding Mill Machine is suitable for processing various non flammable and explosive ores with Mohs hardness below grade 7 and humidity below 6%, such as gypsum, talc, calcite, limestone, marble, potassium feldspar, barite, dolomite, granite, kaolin, chalk stone, bauxite, iron oxide red, coal, glass, calcium carbonate, fluorite, clay, white mud, mica and iron ore.

The fineness of the finished product is between 613 microns and 440 microns

If you are not sure whether your material can be processed. Welcome to consult us online.

By adjusting the analyzer and fan, Raymond mill can meet the use requirements of different users.

Application of Raymond Roller Grinding Mill Machine

Raymond Roller Grinding Mill Machine after years of practice and continuous improvement, its structure has become more and more perfect. Therefore, it is widely used in the grinding and processing of mineral products and materials in metallurgy, building materials, chemical industry, mining and other fields.

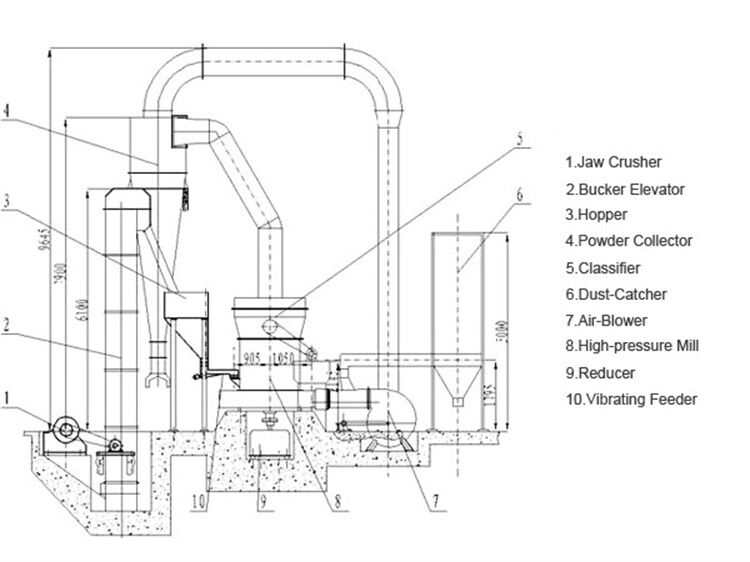

Raymond Roller Grinding Mill Machine Structure

Raymond mill is composed of grinding unit, reduction gear, classifier, pipe line, blower, dust collector, jaw crusher, bucket elevator, electromagnetic feeder and electronic control system.

Working Principle of Raymond Roller Grinding Mill Machine

Advantages of Raymond Roller Grinding Mill Machine

1. Small floor area.

2. Energy-saving.

3. Stable performance.

4. Durable.

5. Easy maintenance.

6. Easy to adjust.

7. Intelligent operation.

8. Environment friendly.

Pay Attention/Operating Instructions

1. Before starting the machine, check the lubrication of belts, screws and all parts, and remove sundries around the machine.

2. Put the raw materials to be ground into the hopper and adjust the gap between the two grinding rollers. During operation, keep the tightness of both ends of the grinding roller consistent. The grinding shall not be too tight and the linear speed shall not be too high.

3. During milling operation, the flow of processing materials shall be strictly prevented. Before shutdown, the grinding rollers must be separated first to prevent direct contact between the two grinding rollers, and pay attention to the storage capacity of the material barrel.

4. The processing materials of Raymond mill must be screened. If the flat screen is blocked, tap it gently to avoid excessive force.

5. Don't roll the grinding roller too tightly. Don't use too blunt grinding teeth to avoid too high temperature. In case of fire or explosion, loosen the rolling distance of the grinding roll immediately to make the abrasive flow down and extinguish the flame.

YGM Raymond Roller Grinding Mill Machine Parameter

| Model | YGM7815 | YGM8314 | YGM9517 | YGM4121 | MTM1600 | |

| Roller | quantity(piece) | 3 | 3 | 4 | 5 | 6 |

| Diameter(mm) | 260 | 270 | 310 | 410 | 440 | |

| Height(mm) | 150 | 140 | 170 | 210 | 270 | |

| Ring | Inner Diameter(mm) | 780 | 830 | 950 | 1280 | 1600 |

| Height(mm) | 150 | 140 | 170 | 210 | 270 | |

| Feeding Size(mm) | 15 | 20 | 25 | 30 | 35 | |

| Finished Size(mm) | 0.613-0.033 | 0.613-0.033 | 0.613-0.033 | 0.613-0.033 | 0.613-0.033 | |

| Motor Powder(kw) | 18.5 | 22 | 37 | 75 | 132 | |

| capacity(t/h) | 1-3 | 1.2-4.6 | 2.1-5.6 | 2.8-10.5 | 5-20 | |

| Overall Dimension(mm) | 4300*3500*5100 | 5300*4100*5200 | 7100*5900*7900 | 9200*7250*9700 | 12550*5700*8250 | |

Who we are?