What are the commonly used equipment in the milling production line? how to choose?

Stones can be used as raw materials for infrastructure after grinding and processing, and the market demand is also large. The grinding production line has an irreplaceable role in various industries.

More and more investors are turning their attention to the powder industry. But for those who have just entered the industry, how to choose the equipment for the milling production line has become a difficult problem.

As a professional pulverizer manufacturer, CLIRIK will introduce the common equipment for milling production line in detail below.

1. Primary crushing - jaw crusher

When crushing stones, we usually choose jaw crushers. When crushing materials, we mainly rely on two jaw plates to squeeze and bend the materials. The movable jaw and the fixed jaw form a crushing cavity with a large upper and a lower small. Realize the crushing of materials.

Advantages:

Simple structure, light machine weight, saving a lot of manufacturing costs, easy maintenance, large crushing ratio, high crushing efficiency, uniform product size, large size of the feeding port, and not easy to block.

Disadvantages:

The lining plate of the jaw crusher is easy to wear, the energy consumption is high, and the vibration is large.

2. Secondary crushing - cone crusher, impact crusher.

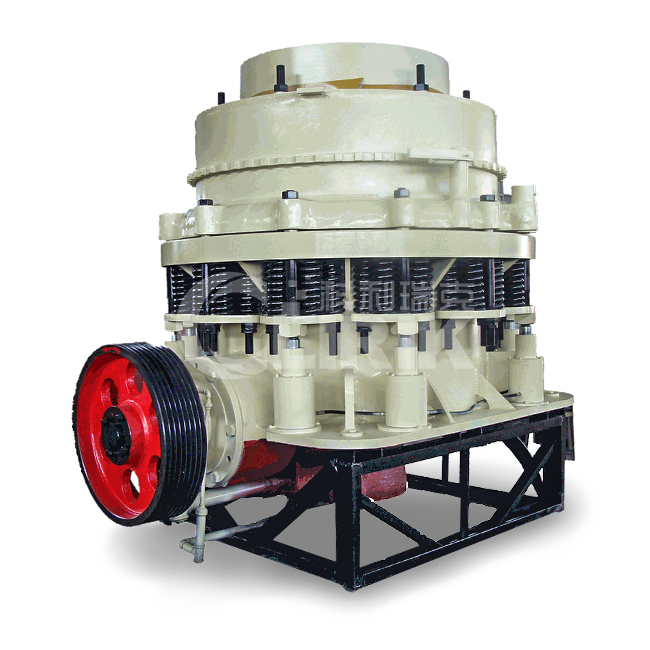

Cone crusher

The cone crusher usually performs secondary crushing on the stone with higher hardness. It adopts the principle of lamination and uses the crushing cone to perform a gyratory motion in the cone cavity in the shell, which has the effect of extrusion, splitting and bending on the material. Suitable for medium or fine crushing operations.

Advantages:

The crushing cavity is deep, which can work continuously and stably, the unit power consumption is also low, the operation is stable, the vibration is light, the machine weight is light, and it can be crowded with ore. Larger cone crushers can The raw ore is directly fed, eliminating the need for a silo and a feeder.

Disadvantages:

The installation and maintenance are more complicated, the maintenance is inconvenient, the rotating body is too high, and the energy is 2-3 times higher than that of the jaw crusher, which indirectly increases the construction cost of the workshop, and the price will be slightly more expensive.

Impact Crusher

The impact crusher usually uses the impact energy to achieve the crushing of soft materials, and adjusting the gap between the impact frame and the rotor can achieve the purpose of changing the material discharge size and shape.

Advantages:

Small footprint, simple structure, large crushing ratio, strong production capacity, and uniform product particle size, and can also be selectively crushed.

Disadvantages:

The blow hammer and the counterattack plate are easy to be worn. If the hard stone is broken, the wear will be even worse, and it needs to be replaced frequently. It is not suitable for plastic and viscous materials to be broken.

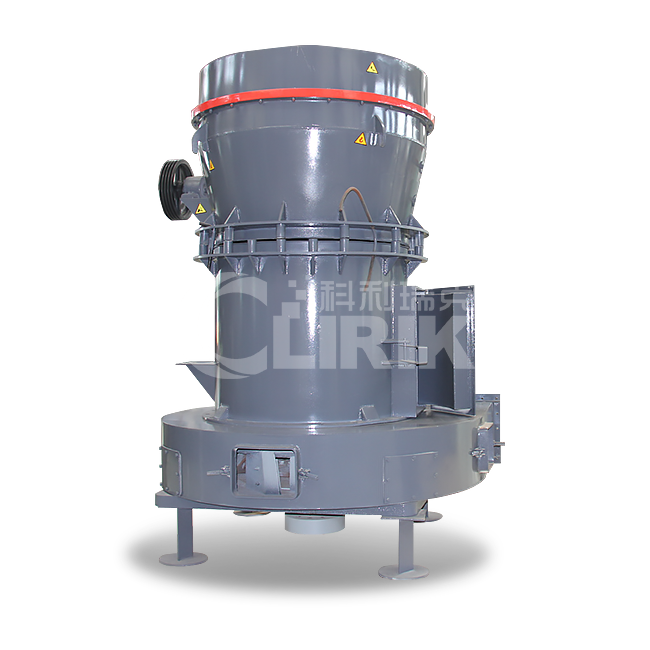

3. Milling equipment - Raymond mill

Raymond mill is a commonly used grinding equipment, and its cost performance is very high. It is suitable for grinding more than 200 kinds of materials, and is recognized and welcomed by most users.

Advantages:

simple and firm structure, convenient operation, strong adaptability to materials, can achieve 325 mesh grinding, good sealing, and effectively prevent dust from flying.

Disadvantages:

The consumption of the grinding body and the liner is large, easy to wear, the utilization rate of electric energy is low, and most of the electric energy is converted into heat source and sound and disappears.

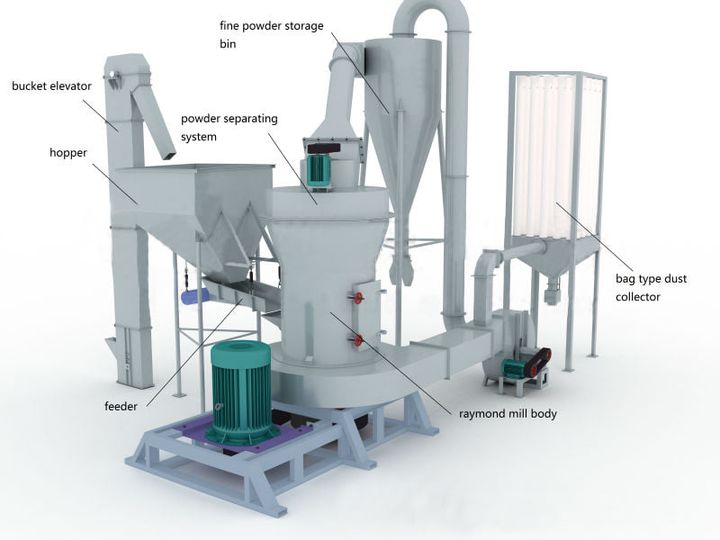

There are also some other auxiliary equipment, such as feeders, vibrating screens, conveyors, etc.

What equipment does a Raymond mill include?

Raymond mill is small in size and takes up less space. It is mainly composed of a host, analyzer, fan, finished product cyclone, micro-powder cyclone, and air duct.

Among them, the main engine consists of a frame, an air inlet volute, a blade, a grinding roller, a grinding ring, and a cover.

In actual production, if only grinding is required, then these equipment can be configured, but in most cases, the particle size of the raw material cannot directly meet the feeding requirements of the mill, and it needs to be crushed first, then it needs to be configured.

A crusher, in general, the average particle size is greater than 150mm, it needs to be equipped with a jaw crusher, if it is less than 150mm, it can be equipped with an impact crusher or hammer crusher.

How much does it cost to configure a Raymond mill?

The quotation for a single Raymond mill ranges from US$10,000 to US$160,000, covering small and large sizes. The larger the model, the higher the price.

Due to the different processing requirements of users, the specific production configuration plans are different, and the quotation is not fixed.

There are many manufacturers of Raymond mills on the market, and each manufacturer has different quotations, and the quotation is affected by various factors such as model, brand, market, and region.

What factors determine the price of Raymond mill?

1. Quality

First of all, the factor affecting the price of Raymond mill must be its own quality. High-quality products generally require more advanced production technology and more reliable manufacturing materials, so the price will be higher.

2. Model

Different types of Raymond mills are suitable for different production requirements, and the prices are also different, because the amount of manufacturing materials used by different types of equipment is different, and the cost is different.

3. Labor cost

Labor cost is an important part of the cost of Raymond mill. The price of Raymond mill produced in areas with high labor costs will be relatively high. On the contrary, in places with low labor costs like Henan, the price will also be higher. Therefore decreased.

4. Market factors

When the supply of Raymond mills on the market exceeds demand, the price will generally decrease, on the contrary, the price of Raymond mills will generally increase