Raymond Roller Grinding Mill Machine for 20TPH Calcium Carbonate Powder Making

Date:2021-08-05 Views:2313

Calcium carbonate, which is what we often call lime stone, limestone, marble, etc., is a common industrial raw material.

Calcium carbonate needs to be ground before application, and calcium carbonate grinders are often used.

Depending on the number of grinding meshes, Raymond mills, ultra-fine mills, micro-grinders, high-pressure mills, etc. can be selected. One of the most commonly used is the Raymond Mill.

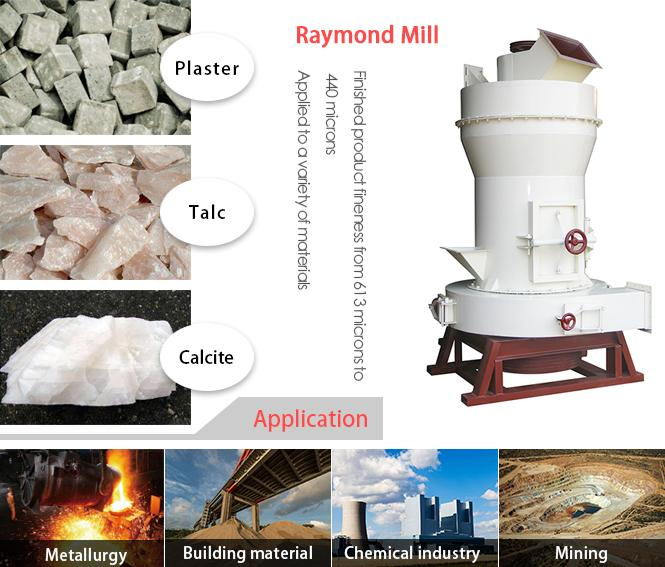

Raymond roller grinding mill machine available materials

Raymond roller grinding mill machine is a commonly used milling equipment, mainly used for calcium carbonat, barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphorus.

High-fine powder processing of more than 280 kinds of materials such as ore, gypsum, glass and thermal insulation materials with a Mohs hardness of not more than 9.3 and a non-flammable and explosive mineral, chemical, construction and other industries with a humidity below 6%.

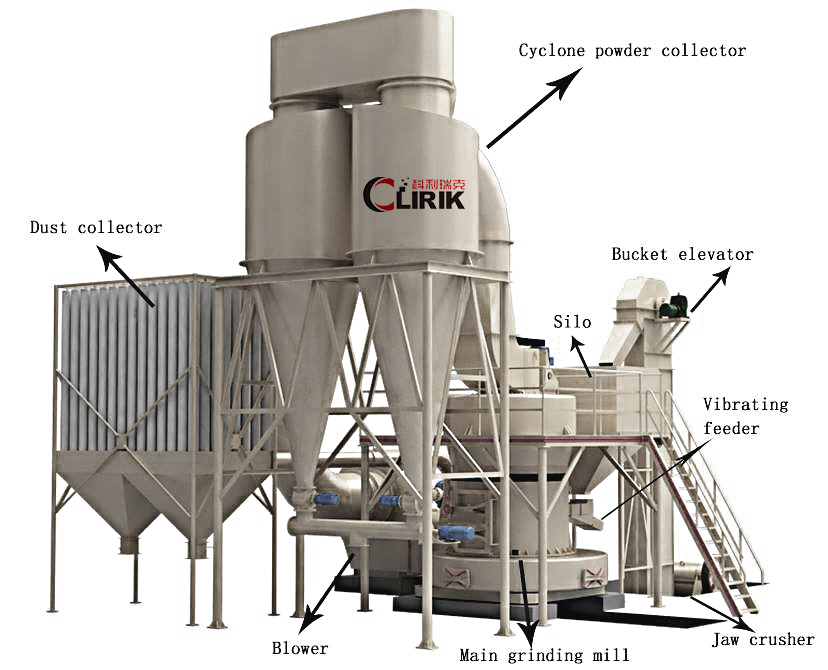

Raymond roller grinding mill machine for calcium carbonate structure

The internal structure of the Raymond roller grinding mill machine for calcium carbonate is relatively simple. It is mainly composed of several parts such as machine, motor, blower, analysis machine, pipeline device, etc. The main machine is the main part of the equipment, including grinding roller, grinding ring, shovel, and inlet. Wind volute, frame, cover, etc.

Grinding principle of Raymond roller grinding mill machine for calcium carbonate

The Raymond roller grinding mill machine for calcium carbonate is a vertical structure, with grinding rollers, grinding rings, blade systems, spring devices, etc. inside.

When the grinding mill is running, the operation of the reducer drives the central shaft.

There is a plum blossom frame on the central shaft, which is connected to the mill The roller forms a swing fulcrum. A grinding cavity is formed between the grinding roller and the grinding ring.

The shovel system sends the mineral material into the grinding cavity.

The grinding roller is pressed against the grinding ring under the action of centrifugal force, and is located between the grinding roller and the grinding ring.

The material in the room is crushed due to the rolling of the grinding roller. The analyzer drives the blades on the turntable to rotate through the speed-regulating motor to classify the powder.

The qualified finished powder enters the cyclone collector, passes through the closed air discharger, and the discharge port After being collected, the unqualified powder is thrown by the blades to the outer wall and separated from the air flow, and the coarse powder falls into the grinding device due to gravity and is repeatedly milled until it is qualified.

When the grinding mill is running, the operation of the reducer drives the central shaft.

There is a plum blossom frame on the central shaft, which is connected to the mill The roller forms a swing fulcrum. A grinding cavity is formed between the grinding roller and the grinding ring.

The shovel system sends the mineral material into the grinding cavity.

The grinding roller is pressed against the grinding ring under the action of centrifugal force, and is located between the grinding roller and the grinding ring.

The material in the room is crushed due to the rolling of the grinding roller. The analyzer drives the blades on the turntable to rotate through the speed-regulating motor to classify the powder.

The qualified finished powder enters the cyclone collector, passes through the closed air discharger, and the discharge port After being collected, the unqualified powder is thrown by the blades to the outer wall and separated from the air flow, and the coarse powder falls into the grinding device due to gravity and is repeatedly milled until it is qualified.

Models of Raymond roller grinding mill machine for calcium carbonate

| Model | Roller | Ring |

Feeding Size(mm) |

Finished Size(mm) |

Mill System Power(KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

|

Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1.0-3.0 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12.0 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16.0 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8.0-20.0 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28.0 | 11550*9500*10500 |

Performance advantages of Raymond roller grinding mill machine for calcium carbonate

1. The CLIRIK calcium carbonate grinder is made of highly wear-resistant materials and new technology. The wear-resistant parts are also made of high-performance wear-resistant materials, which make it have strong wear resistance and impact resistance, and extend The service life of the equipment is reduced, and the maintenance cost is reduced.

2. It adopts a vertical structure with a very small footprint, and the complete set of equipment has very strong performance. From the grinding of calcium carbonate to the packaging of calcium carbonate powder, it can be completed independently without the help of other equipment.

3. The sieving efficiency of the calcium carbonate obtained by grinding is very high, which can be as high as 99%, which is not available in other equipment, and the particle size of the finished product is also very uniform and the particle shape is complete.

4. The sealing performance is very good. The main transmission device adopts a sealed gear box and pulley to make the equipment run more smoothly, prevent dust from entering the body, and effectively improve the working environment.

5. The degree of automation is very high, and the centralized control ability of the electrical system is very strong. Basically, unmanned operation can complete the work well, reducing the labor intensity, saving time and effort.

6. The effect of energy saving and consumption reduction is good, and environmental protection measures are also in place. Low-carbon and environmentally friendly production is realized, operation and maintenance are also very convenient, and the downtime of equipment during maintenance is shortened.

Debugging work of Raymond roller grinding mill machine for calcium carbonate

1. Before the free technical consultation of the no-load operation, the grinding roller device should be tied firmly with a rope to avoid contact with the grinding ring. The free technical consultation of the main engine should not be less than one hour, and the oil temperature should not exceed 80 degrees when the main engine is running.

2. The blower should be turned on under no-load conditions, and then load after normal operation, and then observe whether there is abnormal noise and vibration. Also note that the temperature of the rolling bearing cannot exceed 70 degrees, and the temperature rise cannot exceed 35 degrees.

3. The free technical consultation time for load operation should not be less than 8 hours. After the Raymond roller grinding mill machine for calcium carbonate is working normally and the whole machine does not have any abnormal noise, and there is no abnormality in the connection of each pipe connection, then the various components can be connected. Fix it firmly, and then you can use it normally.

Raymond roller grinding mill machine for calcium carbonate Manufacturers

The grinding accuracy and purity of the Raymond roller grinding mill machine for calcium carbonate depends on its quality and technological level.

Therefore, when choosing a Raymond roller grinding mill machine for calcium carbonate, you need to choose a Raymond mill manufacturer with reliable quality and advanced technology.

Shanghai CLIRIK Machinery Co.,Ltd. has specialized in the research of grinding mills for more than 20 years. CLIRIK's mill can process calcium carbonate powder and modified calcium carbonate powder with various finenesses from 30 mesh to 3000 mesh. CLIRIK is a calcium carbonate manufacturer worthy of your trust. Welcome to inquire.

You can leave a message online or contact CLIRIK directly:

You can leave a message online or contact CLIRIK directly:

Email: sales@clirik.com

WhatsApp: +8613512155195/+8613917147829